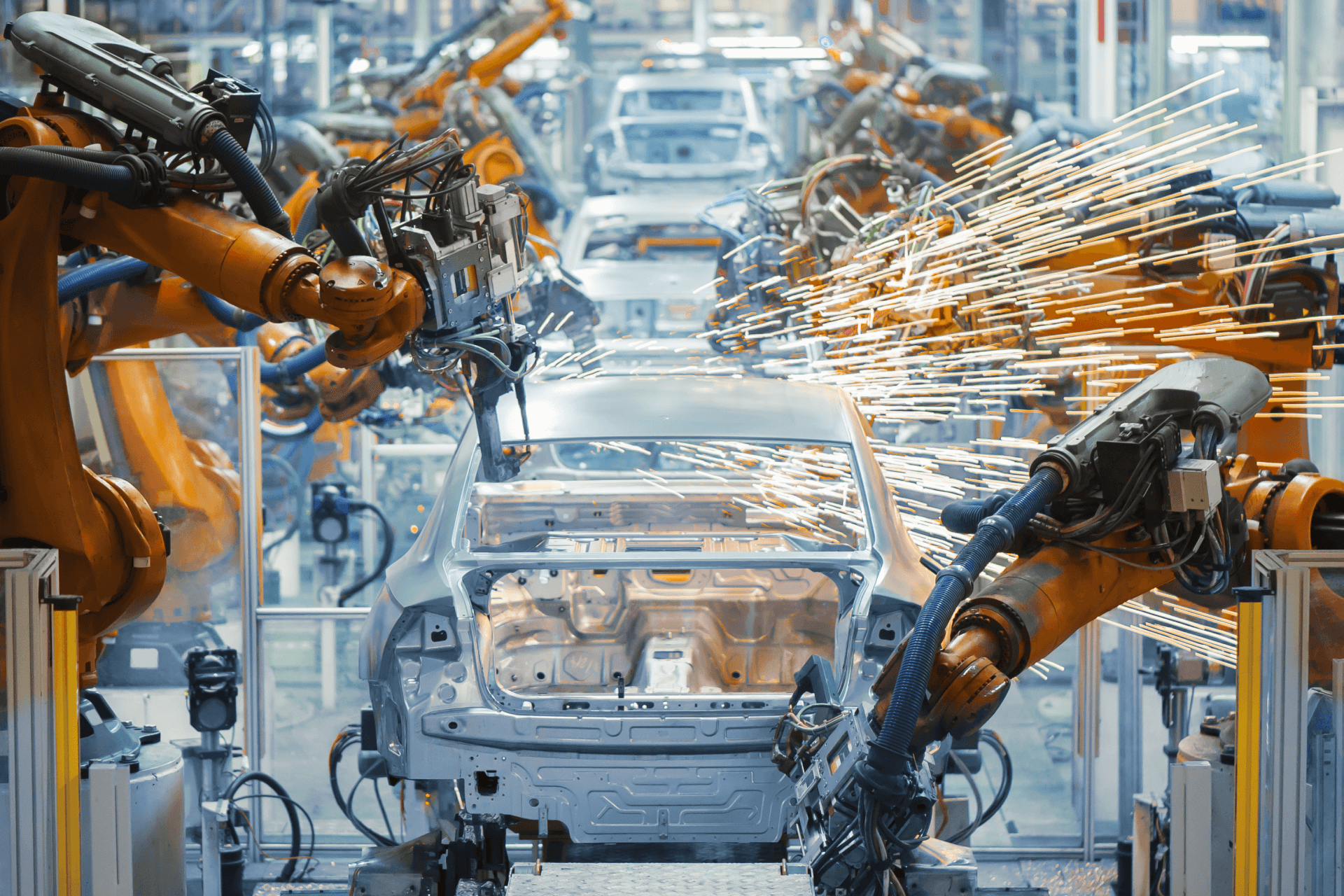

Using AI and Data Annotation to Enhance the Car Manufacturing Process

When we think of AI in the automotive industry, the first thing that usually comes to mind is autonomous vehicles. While this is one of the most interesting and exciting ways of using AI, there are many other ways AI could be applied in the automotive sector. One great example is how Audi is using AI to improve the quality assurance process of how welding processes at its site in Neckarsulm, Germany. Let’s take a closer look at how AI can be used to enhance the manufacturing process and how the AI is trained to differentiate high-quality welding from poor quality.

Checking the Welding Quality in High Volume Production

Using AI to check the quality of welding work is a pilot project that is being advanced by Audi in partnership with Audi and with Siemens and Amazon Web Services as part of the Volkswagen Group’s Industrial Cloud, and is set to be rolled out at other locations. Around 5,300 spot welds are required to join the parts that make up the body of an Audi A6. Currently, the QA process is being done with the help of ultrasound and requires a lot of manual work. This is why the new AI system would be so beneficial since it would significantly improve efficiency by eliminating these manual processes and enhance the overall quality and safety of the vehicles.

The underlying algorithm, its graphical user interface (dashboard), and an application for more in-depth quality analyses are currently being piloted in Audi A6/A7 car body manufacturing at the Neckarsulm site. The aim of the project is for the algorithm to evaluate close to 100 percent of the set welding points during body manufacturing in the future. Hopefully, when the technology matures, the quality of welding processes can be controlled automatically and improved continuously.

This project is part of a broader initiative by Audi to improve manufacturing and logistics processes through digitalization. Innovative technologies are already helping employees and relieving them of strenuous physical tasks and monotonous manual tasks.

How Can AI Determine Good Welding From the Bad?

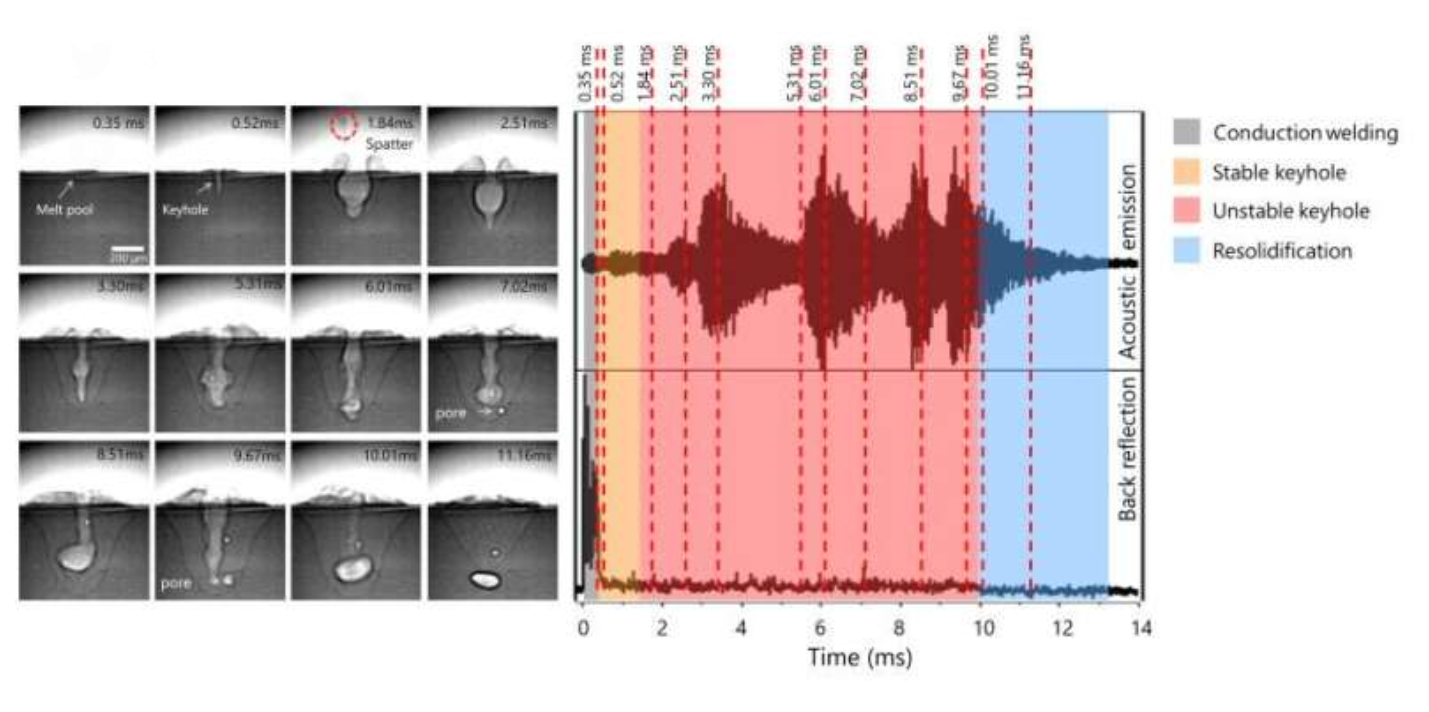

AI systems can differentiate high-quality welding jobs from poor quality if it is trained with sufficient data, which has been annotated by humans to detect the needed details. To better understand how this works, let’s take a look at the image below:

In the above image, we see that there are factors like melt pools, keyholes, and pores that make up the welding process. Each of these things needs to have exactly the right dimensions for the welding job to be deemed as high quality, low quality, or something in between. This means that human data annotations would need to label these factors, but also conduct more advanced data annotation, such as semantic segmentation to allow the system to detect all of the possible variations of keyholes. In addition to this, the AI system needs to understand all of the fine details of welding. For example, when the laser beam passes through a layer of metal beads and welds them together, pores could appear which means that the laser would need to be directed towards the defective area a second time to remove each pore subsequently.

All of these fine details would need to be accounted for in the training data and, consequently, annotated to allow the system to detect them.

AI Could Be Used to Improve Welding Beyond the Automotive Industry

The application of artificial intelligence in the field of welding is an increasingly important area of research. AI could help solve many welding challenges such as poorly controlled welding parameters and weld geometry, which lead to weld quality problems. In recent years, the volume of welding and assembly work at open assembly sites has been increasing. The need to use advanced methods of mechanized and automatic welding in shielding gas is obvious, but the effect of disturbing factors, including climatic factors, makes them difficult to apply. The complexity of the welding process under the influence of disturbing factors complicates its adjustment by the welder.

AI could offer adaptive controls that are based on optimization algorithms, search, classification, and clustering that can help solve these and other problems.

Trust Mindy Support With All of Your Data Annotation

Using AI to ensure welding quality in automotive and possibly other sectors could lead to significant improvements in the welding process, but such AI systems require significant amounts of data annotation to ensure that it can differentiate the various level qualities. Data annotation can be tedious and time-consuming work which is why so many companies outsource their data annotation needs to Mindy Support. We are the largest data annotation company in Eastern Europe with more than 2,000 employees in eight locations all over Ukraine and in other geographies globally. Contact us today to learn more about how we can help you.