Robotic Process Automation Taking Over Manufacturing

With the global automation market reaching $185.9 billion this year, robot process automation (RPA) is now being used by companies across various industries and the manufacturing sector is no exception. This should not come as a surprise since robots are capable of eliminating redundant, manual processes, perform hazardous jobs and improve the overall quality of the products that companies manufacture. Even though today only 10% of the manufacturing jobs are automated, many experts believe that this number will increase to 25% by 2025 as robotic vision and gripping sensors improve. With this mind, let’s take a look at some of the jobs that are already being automated.

Drilling and Fastening

Drilling and fastening machines are already being used on assembly lines in aerospace, automotive, and many other industries. They allow companies to maximize the quality of the products while reducing manual labor. For example, ThyssenKrupp Systems developed a robot that can drill through various materials used in airplane manufacturing thus eliminating time-consuming, redundant tasks while reducing the error rate. For humans to drill through titanium requires a multi-step setup process in addition to the actual drilling. In airplane manufacturing, this process would need to be repeated many different times throughout a single day, so we can imagine the saving in time and resources such as technology offers companies.

One of the reasons why these robots are able to provide such a high level of precision is because they are equipped with computer vision cameras and LiDAR that are able to calculate the exact drilling location. In order to train the machine learning algorithms to do their job correctly, a lot of data annotation work needs to be done to show the machine what the assembly process looks like and where it needs to drill. The more data that is available for such systems to learn from, the higher the quality will be.

Robotic Product Inspection

After the manufacturing process is complete, companies have to perform a rigorous quality assurance process to make sure everything they are sending out the consumer meets the highest standards. In the past, this was done by humans who walked around with pens and clipboards inspecting all of the items thus causing bottlenecks. Nowadays, there are all kinds of robots that can automate this process. One interesting example is the Stormer Model S3000 Pipe Crawler that is equipped with a computer vision camera that can detect the slightest defects in a pipe. What makes this robot so efficient is that it crawls inside pipes anywhere from 150 to 1000 mm in diameter, something that would be impossible for humans to do.

Robots that need to function in their immediate surroundings rely on camera and LiDAR technology (a sensor designed to quickly build 3d point clouds). This is basically a visual representation of the world as seen by the robot. Later on, these lidar scans will need to be annotated so the robot knows the exact dimensions of the pipe and can navigate its way out. Also, since its main job is to look for defects, it needs to be trained to identify them. Researchers need to take thousands and thousands of images, containing all kinds of defects, and feed it into the system for the machine to learn and later recognize. Since these defects can come in all shapes, sizes, and variations, it would be best to annotate as much data as possible since this will increase the overall accuracy of the robot performance. `

Robotic Assembly

Believe it or not, robots have been used in the automotive assembly line for more than 50 years, and their applications are still growing. For example, Universal Robots have created a robot arm that reduces production time and can be deployed in many environments. Such robots are being used by car manufacturers for door panel, windshield, and fender installation. These robots are more accurate than the ones used by many manufacturing companies in the past since they are powered by computer vision which provides a higher level of accuracy. In addition to the manufacturing sector, these robots have many other applications such as working in dangerous environments and jobs where high quality and precision are critical.

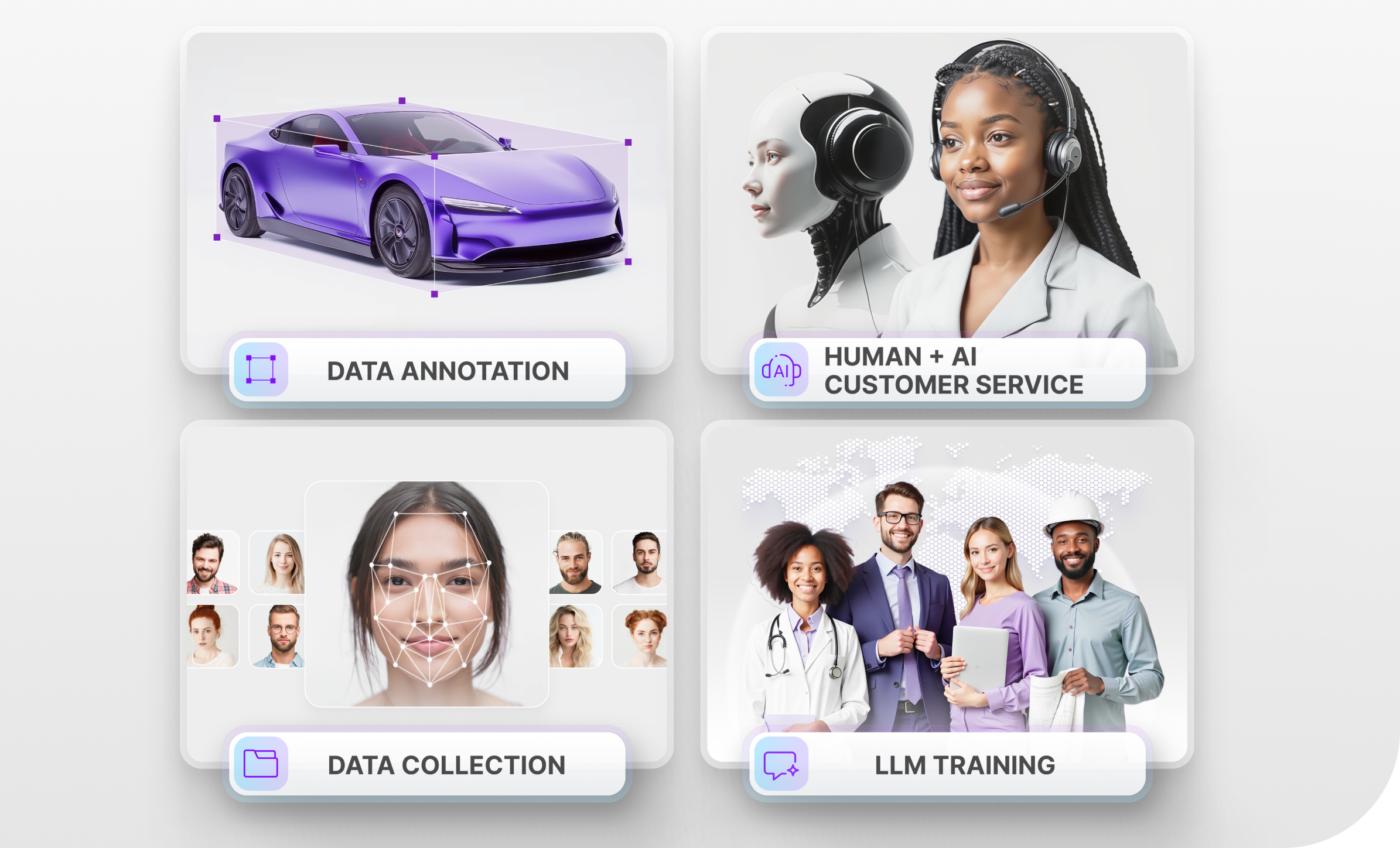

Mindy Support is Facilitating the Development of Next-Generation Robots

Mindy Support is one of the largest BPO providers in Eastern Europe with more than 2,000 employees across six locations in Ukraine. Our size and location allow us to source and recruit candidates quickly to help you meet deadlines. We can scale your team quickly without sacrificing the quality of the work which is why SMEs, several Fortune 500, and GAFAM companies trust us with their data annotation needs. Contact us for a free trial in data annotation.