Manual Processes in Warehouses are Costing US Companies $4.3 Billion Every Year

One of the biggest challenges companies in the logistics industry are struggling with is a shrinking workforce. In order to fully illustrate how big of a problem this actually is, 45% of companies all over the world report that they are struggling to fill vacancies. Also, more than 25% of the workers in the global supply chain are beyond the retirement age. If we consider that last year e-commerce created 452,000 warehouse and distribution center jobs, there will also be increased demand this year as well since e-commerce is expected to grow by 18% this year. With this in mind, let’s take a look at how companies can use robots and automation to help overcome labor shortages and run their processes with greater efficiency.

Robots in Warehouses

Automation is making a huge impact on warehouses since robots are used to transport materials and streamline all kinds of processes. In order to illustrate the type of efficiency robotic process automation (RPA) offers, let’s take something as basic as walking around the warehouse as an example. The data shows that the average US warehouse wastes an average of 6.9 weeks a year on unnecessary motion. This is costing companies $4.3 billion every year or 265 million wasted hours. Robots are much more efficient in planning their routes to avoid congested areas and can assist human workers by delivering the needed items to them.

For example, let’s take a look at Chuck, a state of the art robot that is helping companies reduce wasted hours. This robot can guide workers through the warehouse to make sure they find what they are looking for right away and can bring certain supplies to the workers since it can haul 200 lbs worth of stuff. There are many other robots out there that can automate the inventory process, retrieve goods, place them back on the shelf, and many other time-consuming things that slowly but surely eat up a lot of time.

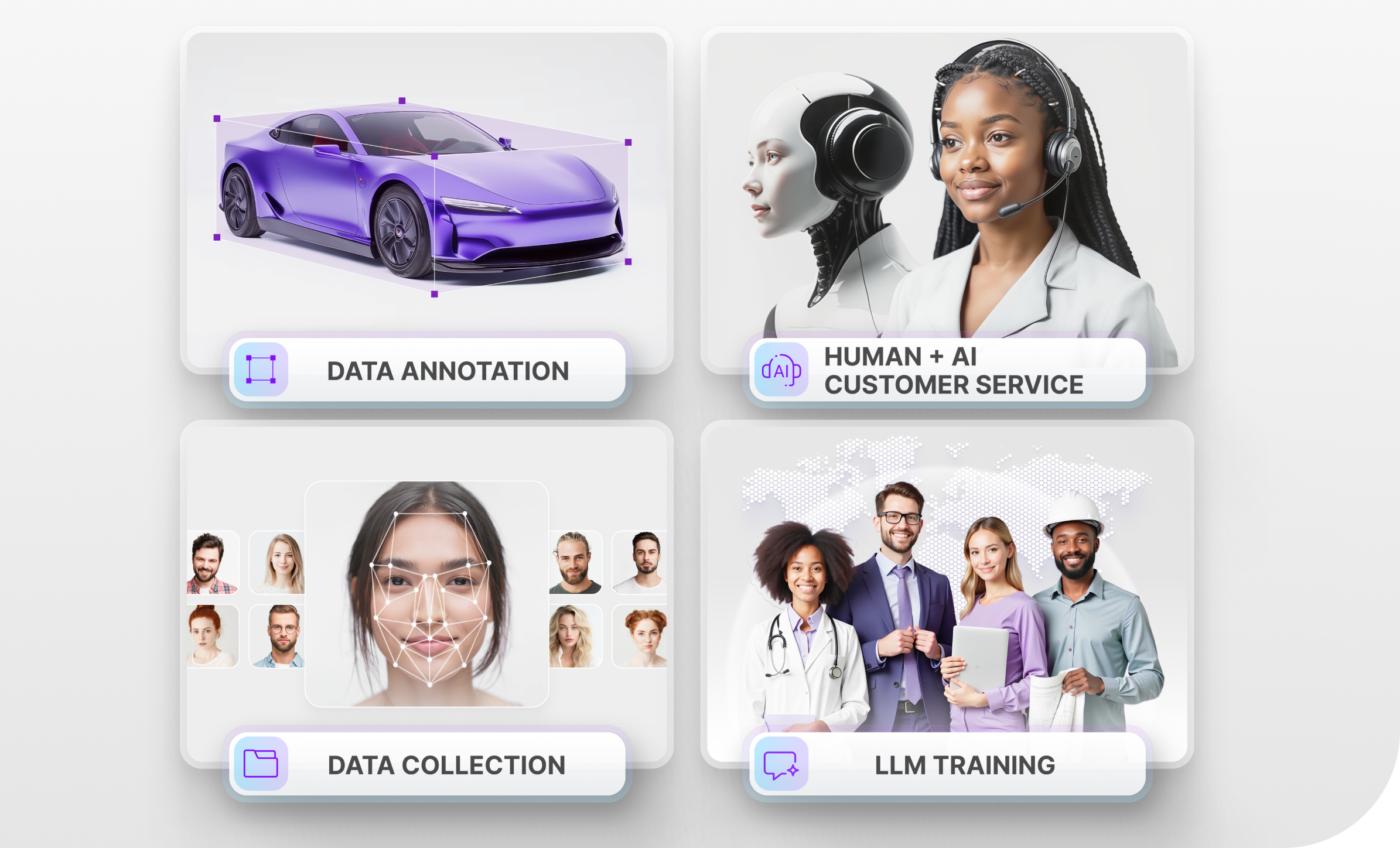

Robots like Chuck and others that can independently navigate their surroundings require lots of data annotation to make sure they are able to identify all of the items in their environment. The robotic vision is made possible by LiDAR technology that produces a 3D point cloud, which is a visual representation of how the robot sees the world. These images will need to be annotated by humans where they will label things like humans, boxes, shelves, and any other items located in the warehouse. The more data you have to train the robot, the more accurate they will be in performing all of their assignments. Also, it is important to note that the quality of the data annotation needs to be at a high level because, as the saying in the data annotation world goes, “Garbage in is garbage out.”

The Demand for Delivery Robots is Skyrocketing

We already mentioned that e-commerce is growing and companies like Alibaba are looking to create logistics networks that can handle 1 billion packages a day. However, this is not the only factor driving up the demand for delivery robots. The coronavirus pandemic has created a need for contactless delivery and RPAs are a very effective solution to this problem. Companies like Starship Technologies are creating robots that can deliver food and online orders quickly and efficiently. Research shows that such sidewalk automated delivery robots (SADR) can produce cost savings of $3-5 per package, which may not seem like a lot, but when we extrapolate this to the number of packages companies like Alibaba are planning to deliver on a daily basis, this adds up to significant cost savings. It is also worth mentioning that as the COVID-19 crisis continues this year and well into next year, this will continue to increase demand for SADR in addition to all of the savings it offers.

Just like the Chuck robot mentioned above, the SADR robots rely on LiDAR and 3D point cloud, but they require a lot more data annotation. For example, they need to be able to deliver the package to the right person, which means they must be able to recognize their face. This requires facial recognition technology which uses landmark annotation which is placing points on a person’s face to identify unique facial features. Also, there will need to be a lot of tagging. 2D/3D bounding boxes and even semantic segmentation work done since there are so many thighs the robot might encounter in a real-world environment.

Mindy Support is Helping Researchers Develop Next-Gen Robotics

Mindy Support is one of the largest BPO companies in Europe. Our size and location allow us to source and recruit the necessary amount of candidates within a short time period. We can scale your team quickly without sacrificing the quality due to the rigorous QA processes we have

in place. This is why we are trusted by a number of Fortune 500 and GAFAM companies to perform all kinds of BPO tasks since we have the capabilities to perform the necessary work on such a large scale.

Posted by Il’ya Dudkin